Expert Mold Design: Leading Solutions in Houston

It’s projected that the global injection molded plastics industry will swell to $440 billion by 2025. This growth underlines the importance of professional mold design services. They create high-quality custom mold designs for diverse industries. Among Houston companies, Lowrance Machine is renowned for mold design. Their expertise spans automotive, aerospace, and consumer-product mold design.

Leveraging CAD platforms and 3D-printing technology, Lowrance Machine. Their experts guarantee both accuracy and speed throughout molding. Backed by deep expertise and technical know-how, they remain a trusted business ally. Explore how their mold design Houston services can improve your projects and meet today’s market demands.

Understanding the Importance of Mold Design Services

Quality and efficiency in manufacturing hinge on expert mold design services. The role of mold design is immense; it shapes the performance and longevity of products. By prioritizing professional mold design, firms reduce costs and improve quality measures.

Seasoned professionals at Lowrance Machine illustrate the benefits of expertise. They engage closely with clients to develop tailored designs. By employing cutting-edge methods like 3D modeling and CAD, they help businesses create molds that adhere to high standards.

Opting for premier mold design services elevates product functionality and powers business growth. With optimized mold design, manufacturing runs smoothly and firms gain market advantage.

Mold Design Houston: Types of Services Offered

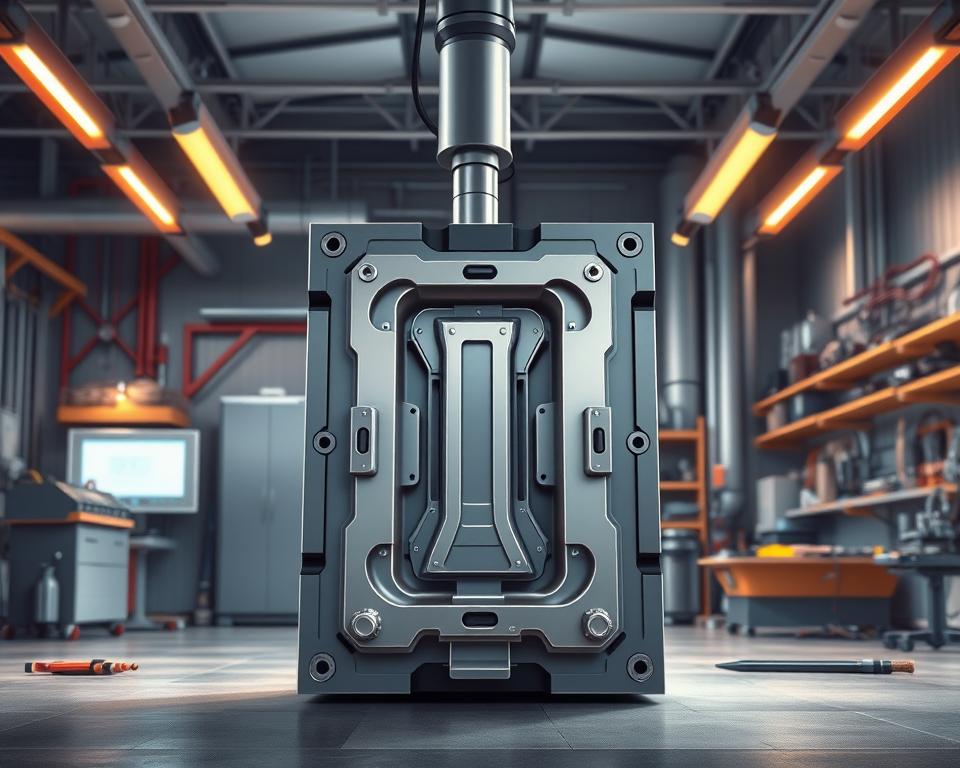

At Lowrance Machine in Houston, you’ll find varied mold design solutions designed for every industry. Knowing the different types of mold services helps businesses choose the best for their projects. Key categories include:

- Design Services: Tailored mold designs crafted to precise specs.

- Test Mold Creation: Prototype mold development for pre-production testing.

- Injection Molds Houston: Precision-engineered injection molds built to last.

- 3D CAD Modeling: Advanced CAD to develop exact 3D mold prototypes.

- Repair and Maintenance: Services aimed at extending the lifespan of existing molds through essential repairs and maintenance.

These services collectively enhance throughput, raise quality, and cut expenses. By understanding the available mold services, industries can better meet their manufacturing needs.

Advantages of Expert Mold Design Partners

Engaging professional mold design teams offers significant process improvements. Gain improved accuracy, robustness, and throughput. Bespoke design drives superior product standards and uniformity.

Seasoned teams provide critical workflow enhancements. They certify molds comply with both generic and custom criteria. Working together drives creative solutions and lengthens product durability.

Cost-effectiveness is a significant benefit. Modern techniques curb scrap and shorten lead times. Such efficiencies translate into meaningful cost reductions. Swift design workflows speed time-to-market, sharpening competitive positioning.

In summary, specialized mold design companies provide critical support for manufacturers. They focus on boosting throughput and product excellence.

Cutting-Edge Mold Design Methods

Innovation has driven monumental shifts in mold design. Lowrance Machine leads the way with its cutting-edge mold design techniques. Such breakthroughs accelerate production and raise standards. Modern engineering tools expedite custom mold fabrication and lower overheads.

3D printing is a standout among these techniques, enabling quick prototyping and complex designs. It significantly reduces material waste compared to traditional methods. Simulation software allows designers to test and refine mold functionality virtually, improving both precision and efficiency.

In Houston, mold design experts are embracing these modern strategies. Firms achieve market edge through digital design and high-tech manufacturing. These technologies enable a more agile and responsive mold design process, meeting a wide range of client needs and market demands.

| Technique | Description | Benefits |

|---|---|---|

| 3D Printing | Harnesses 3D-printer tech for swift mold fabrication. | Reduces lead time and material waste. |

| Virtual Testing Tools | Offers virtual mold performance simulations. | Boosts precision and refines function. |

| Digital Design Tools | Leverages CAD for detailed mold engineering. | Supports bespoke specifications and rapid revisions. |

In Closing

Mold design services are critical for businesses aiming at efficient manufacturing and high-quality production in Houston. Professional mold design services offer expertise to tackle mold development challenges. They customize approaches to align with specific business goals.

Lowrance Machine is a top name in mold design, known for its dedication to precision and collaboration with clients. The benefits of mold design, such as customized solutions and cutting-edge technologies, help manufacturers stay ahead in a fast-changing market. Engaging experts boosts standards and refines processes.

Choosing expert mold design services in Houston prioritizes both excellence and speed. Firms can deliver on client needs while improving their market position. Adopting these specialized services is vital for manufacturers aiming to succeed in today’s competitive environment.